We make printing houses more profitable

ADNOS GmbH was founded with a clearly defined goal: the development of environmentally friendly, economical and innovative complete solutions for the printing industry. Intelligent UV DryerHeatset IR DryerADNOS – Innovation since 1983

Part of our philosophy is to question conventional systems and to find new ways which not only make the work of the printer safer and simpler, but also improve the quality of the printing job, always according to the ADNOS rule that thinking must be done for the design of a system – and not for its operation! Our first product, the intelligent UV-dryer with automatic UV dimmer, demonstrates this philosophy. Here, a worldwide patented intelligent UV dimming technology is used to optimize the hardening process automatically. Today, ADNOS offers a whole range of products proven under the most demanding working conditions at our customers in Germany, Europe and Overseas and designed to solve all your problems around the printing press – guaranteed! This website introduces the ADNOS products. We have tried to answer all important questions that may arise about an individual product, but will be glad to answer any further question that you may have.

ADNOS GmbH was founded with a clearly defined goal: the development of environmentally friendly, economical and innovative complete solutions for the printing industry.

The ADNOS range of products and services:

Mobile and combined UV, IR and nozzle dryers

Excess powder extraction units

Ink mist filter hoods

Sheet guiding devices

Painting and drying systems for special three-dimensional products

Complete solutions for sheetfed presses

Solution tailored to your requirements

Our first product, the regulated UV drying system, makes our philosophy very clear. Our UV dryer uses computer-controlled control technology. The drying process is automatically optimized. We hold worldwide patents for this process. Today, ADNOS can offer you a wide range of products. Our machines have proven themselves in practice to our customers in Germany, Europe and overseas with the best satisfaction.

Intelligent UV drying systems

Reliable drying at any speed

Simple operation

Short set-up times thanks to ADNOS plug-in system

Easy installation in printing presses

Low thermal stress on the printing material and machine

Compact design

Each UV readiator can be controlled individually

Gap usage in stand-by mode with indication of current output level for sheet and metal plate drying

Drying on web-fed presses also without cooling cylinder due to guaranteed low material temperature

Energy save up to 50%

Extremely short start-up and cooling-down time (approx. 1 minute)

The function

In the course of the printing process the freshly printed shet is transported through the UV radiation zone. The microprocessor in the UV dryer measures the printing speed, senses the position and length of the sheet and switches each lamp from the “idle” output level (20% of rated output) to exactly the required output level in approx. 5 ms. Print stock formats whichdeviate from the largest possbile format are also detected by the machine and evaluatedby the microprocessor. For example, if a print format is used which is 55 mm shorter than the standard, the microprocessor switches the UV lamp back to the “idle” output level 55 mm earlier.

Why a UV regulation at all?

You know it from practice: No print job is like the other. The paper quality as well as the properties of the inks and varnishes used vary, as does the respective printing speed or sheet size. It is logical that a rigid setting of the UV dryer cannot always be the best. Adhesive foils, for example, change their adhesive strength when the spotlight output is not matched, while register errors can occur if the substrate is shrunk, and stacking safety cannot be guaranteed. After all, the surplus – wasted – energy has to be dissipated from the printing system at great expense. In order to achieve an optimal printing result, the only acceptable solution is therefore a continuous regulation of the radiation output. The computer-controlled ADNOS UV dryers can be adapted to all the above-mentioned variables.

What does pause power or pause switching mean?

From a technical point of view, it is quite simply that the UV lamps only work on the required radiation output when there is actually something to be irradiated. At the end of the arc, the ADNOS control returns the radiation to a resting power (20%). Thanks to the automatic format detection of the ADNOS systems, this works reliably for all sheet formats. Switching to the desired production output at the next sheet is done with millimetre precision. In practice, this means considerably less heat in the press because only the substrate is irradiated.

What tasks does the computer perform?

As an electronic heart, the computer constantly monitors all the important components of the UV system and the printing press and uses these data to issue commands to the stepless controller, which thus ensures that the lamps always emit the optimum amount of energy. You can also enter information such as color distribution into the computer or set it manuallyl

Why are ADNOS dryers not water-cooled?

First of all, water cooling is not a quality feature, but often a necessary evil. ADNOS UV dryers work with air cooling. This is partly due to the control system, which avoids excessive heat generation. On the other hand, the reflectors of the ADNOS UV dryers are of such high quality that they almost completely reflect the radiation. ADNOS dryers are particularly easy to operate because there is no need for complex water cooling – the replacement or relocation of lamps can be carried out quickly and easily by the printing staff. In addition, the air cooling allows a particularly compact design, which allows UV dryer solutions even on small printing presses where this does not seem to be possible at first glance.

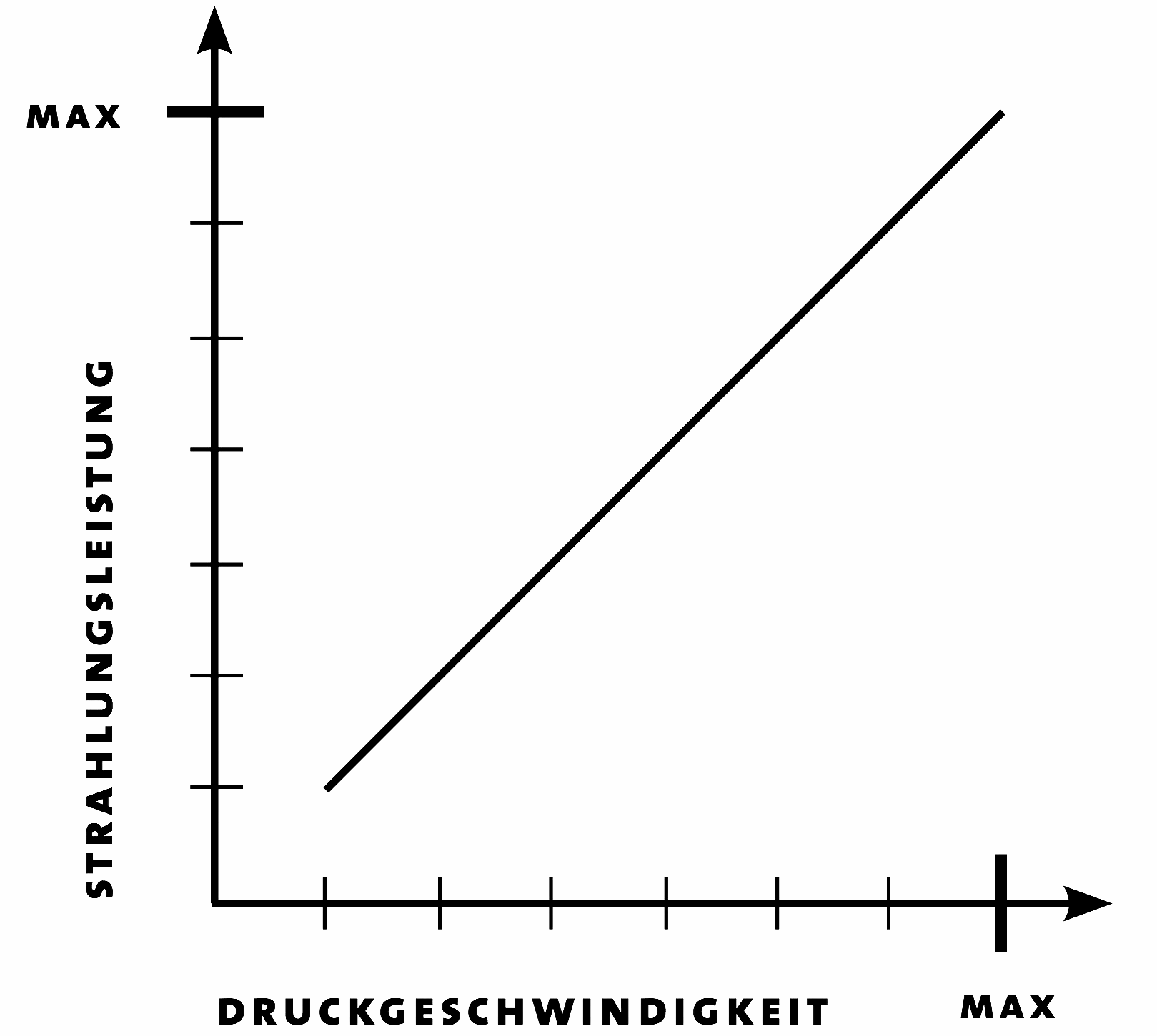

Working characteristic of a regulated ADNOS UV dryer:

When using different printing processes (e. g. book, offset) in the same machine, the radiation power is automatically adapted to the respective printing process.

When is the use of inert gas UV systems necessary?

Whenever particularly sensitive materials need to be coated with low reacting UV substrates. These substrates, when hardened in a normal oxygen environment, would require a huge amount of radiation energy which would damage the printed material. ADNOS has designed special inert gas UV-dryers, which harden UV-inks, -varnishes or coatings under protective inert gas with considerably less energy and thus prevent any damage.

How much energy does the ADNOS intelligent UV and H-UV dryer with UV dimmer save?

Up to 50 % ! We will be happy to work out for you exactly how much energy you can save based on your particular production conditions.

The reflector makes the difference: ADNOS infrared dryer

The features of the ADNOS Heatset infrared dryers:

Durable aluminium reflectors with superior reflection characteristics

Precise design and manufacture of reflectors for optimum radiation density

High efficiency makes it possible to use radiators with considerably lower rated power consumption

Glass breakage sensors monitor the IR radiators and immediately report damage. Essential for every BRC certification!

What is the main difficulty with heatset IR dryers?

In principle, IR dryers have a very simple task: The IR lamps must generate sufficient heat to accelerate the oxidation drying of the printing inks to the desired degree. The difficulty here is to actually apply as much IR radiation as possible to the printing ink and at the same time as little heat as possible to the printing press. The key to solving this problem lies in reflector technology. ADNOS uses precisely calculated and elaborately designed aluminium reflectors. Aluminium is characterized by a particularly long service life and optimum reflection of the IR radiation – better than any other material.

How are ADNOS Heatset IR dryers cooled?

Not at all. IR dryers are designed to generate heat, not cold. ADNOS reflectors, reflect the radiation almost completely. Therefore, they do not get warm enough to require cooling. Since no complex water cooling is required, the efficiency increases considerably. This means that only a fraction of the radiation energy is required.

ADNOS Nozzle Dryer

For all printing processes with oxidative and solvent-based inks and varnishes, as well as dispersion inks and varnishes.

Consistently low solvent concentration in the dryer due to exhaust system

High efficiency and compact dimensions

High efficiency makes it possible to use lamps with considerably lower rated power.

User-friendly and less labour-intensive

What has better air got to do with the efficiency of nozzle dryers?

A lot! When dispersion paints and varnishes are dried, solvents are released in addition to water vapour. In the sense of fast drying, this is actually undesirable. The higher the solvent concentration within the drying machine, the lower the pressure of the evaporating water and the worse the drying. In closed air circulation systems, the continuous recirculation of the air enriched with solvents continuously increases the solvent concentration inside the dryer. Logically, the drying capacity decreases accordingly. ADNOS nozzle dryers therefore work with an exhaust system that removes water vapour and solvent particles immediately and constantly replaces the air in the dryer. In this way, the vapour pressure remains constant at all times and the drying performance, i. e. the efficiency rate, remains consistently high.

Why are ADNOS nozzle dryers so small?

Because efficiency has nothing to do with size, but with good design and applied technology. Thanks to the air extraction employed by ADNOS, the ADNOS air nozzle dryer achieves the same drying effect like conventional systems, however, with far less space needed. This makes the dryer not only very operator friendly, but allows the mounting of the dryer also outside the actual printing area (e.g. above the printing press).

ADNOS excess powder extraction units

Greatly reduced dirt accumulation in the press and therefore, higher product quality and production safety

Greatly reduced ambient air contamination

Easy adaption and uncomplicated installation into any press

Elimination of explosion hazard in the press

Quick amortisation due to considerably longer cleaning cycles

Why are powder extraction units necessary?

Modern, high speed sheet-fed printing presses with an output of 15.000 sheets/h cause air streams which lead to the swirling of powder, no matter how well the powdering unit is adjusted. The swirled powder finds its way into the press where it settles on the greased parts of the last printing station (grippers, chains). The resultant grease and powder lumps jeopardize the quality of a full pile! Also, the powder settles on the rubber blanket which necessitates frequent cleaning of the printing station. A large portion of the powder floats in the ambient air, is inhaled by the press room staff and can cause serious lung deseases such as silicose. ADNOS excess powder extraction units considerably reduce health hazards for both, man and machine!

Does the installation also have economic advantages?

Because of the vastly extended cleaning cycles and greatly reduced downtime of the press, the initial investment for the ADNOS excess powder extraction unit is paid back within a few months!

Is upgrading with ADNOS powder extraction systems complicated?

No. The system can be installed quickly and easily on any printing press.

ADNOS ink mist filter hoods

No contamination of the production rooms due to paint and varnish mist

Improved health conditions for your staff

Improved quality of print

Open design, therefore easy access to the ink fountain

Removal of solvents and vapours via outside air ventilation

Fast and easy changing of filter mats

Fast installation due to adapter mountings

Available for all popular presses and printing formats

Which problems can arise because of ink mist?

The mist from inks and varnishes which is generated at high printing speeds, poses three threats. Firstly, the inkmist settles on impression rollers and plate cylinders and reduces the printing quality. Secondly, it contaminates the air conditioning system of your printing room and last but not least, it is a health hazard for your staff, which is not to be underestimated! ADNOS ink mist filter hoods prevent all this.

Why are ADNOS ink mist filter hoods of open design?

Because the ink fountain is always easily accessible. And a door that doesn’t exist, cannot be left open accidentally. ADNOS has decided to design a system that is always open and thus always works, instead of an enclosed system which doesn’t work when open.

Why complete extraction via the outside air? Would normal filtering not be quite sufficient?

Yes, for the ink mist only! However, vapours from chemicals used on the press for e.g. washing, etc. need to be removed via outside ventilation to avoid air contamination inside the press room.

Does the sucking action on the ink mist filter hood in any way affect the function of the press?

No. ADNOS inkmist filter hoods do not create additional air flow at the press.

How can one see that a filter mat needs to be replaced?

An indicator shows when the filtermat is due for a change. Usually, the mat should be changed once a month.

Adnos sheet guiding devices

Scratch and smear-free sheet transport through the press at any speed

Improved print quality

Easy retro-fitting for any press

What does the ADNOS sheet guiding device?

They ensure that the sheets run through the press without scratching and without ink smear and thus add to the high quality of your printing job. Without sheet guiding devices, some materials will knock against the press in critical areas. The result: scratch marks and smearing. With sheet guiding devices, also particularly light or heavy materials will pass critical areas inside the press with no problem.

Is the standard sheet guiding device of the press not sufficient?

It is, if you don’t have additional equipment installed, don’t run lightweight or heavyweight material and always run at the same speed without variations. This, however, is an ideal condition which is hardly encountered in reality

Which advantages does the ADNOS sheet guiding device offer?

It ensures a proper guiding of the sheet throughout its way through the press even when running particularly thin or thick materials like tin plates or carton. Even at high printing speeds, waving and knocking are reliably prevented.

Does this work also on my printing press?

Of course! ADNOS offers individual engineering and tailor-made systems for each press, which can easily be retrofittend.

Henrik Schaft

Tel: +49 (0)40 606 44 41

Email: henrik.schaft@adnos.de